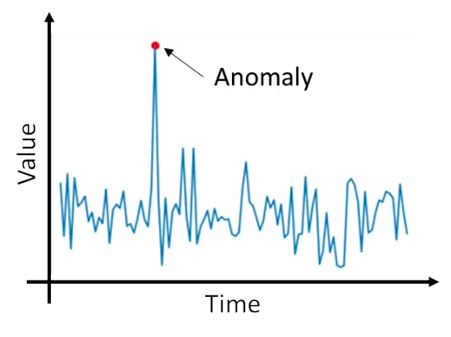

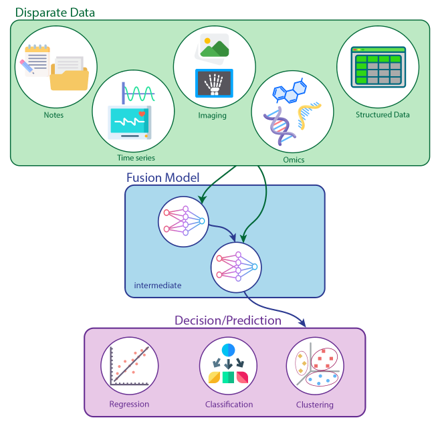

AI algorithms analyze real-time sensor data in a bioreactor and detect deviations from expected patterns, such as sudden drops in dissolved oxygen levels, which could indicate contamination.

Nutrient:

Adjusts the concentration and timing of nutrient feedings in a bioprocess based on real-time cell growth data, maximizing biomass or product yield

Temperature:

Optimizes the heating and cooling systems in a bioreactor to maintain a stable temperature

Yield:

AI algorithms explore various process parameter combinations in silico to find the optimal conditions for producing a high-yield, bio-based product in the shortest time possible.

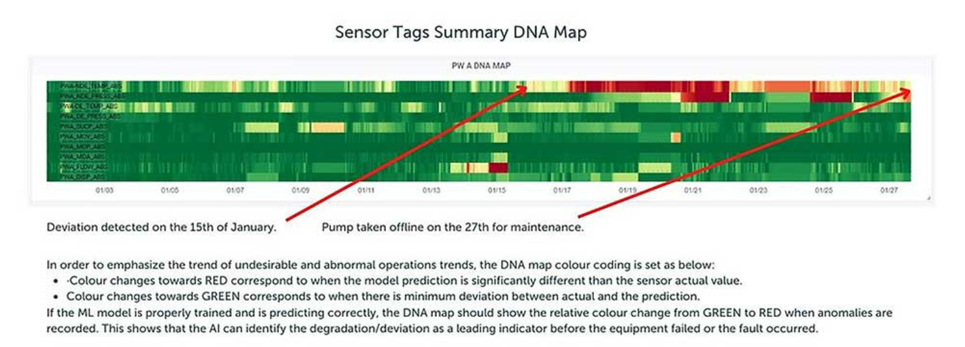

AI models analyze pump vibration data and historical maintenance records to predict when a pump is likely to fail, allowing for timely maintenance to prevent costly breakdowns.

AI monitors the condition of agitators and mixers in real-time, using data such as bearing temperatures and load torque to schedule maintenance before any critical components wear out.

AI analyzes pressure drop data across filtration units and predicts when filters need replacement or cleaning to maintain product quality and prevent clogging.

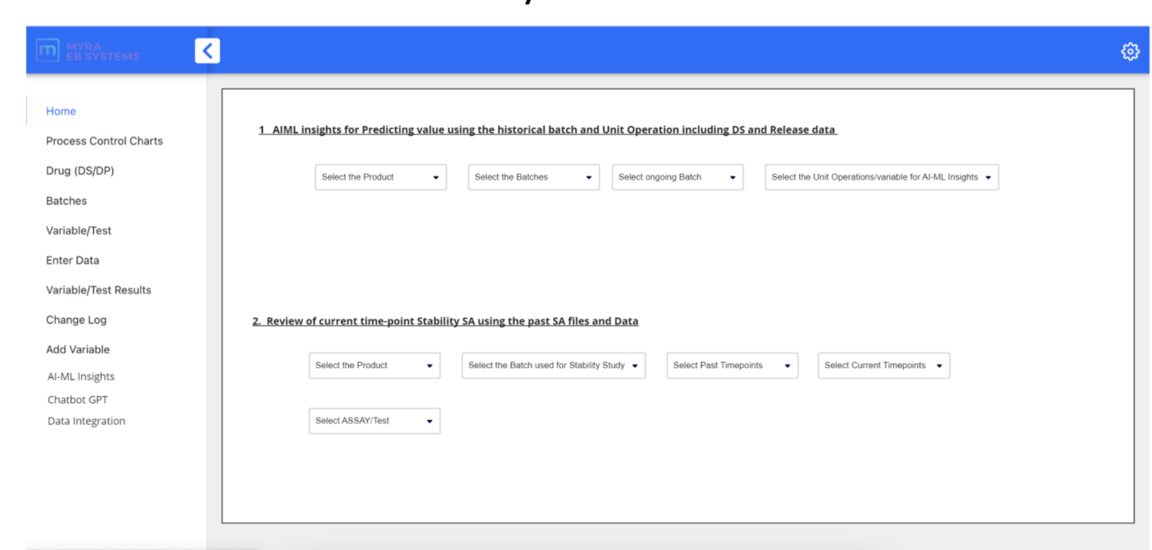

AI algorithms excel at carefully examining stability data, which often includes various assay packages at a single timepoint.

AI can rapidly analyze trained data and give results when the stability data shows a clear pattern.

The data management system is used to provide insights for in process data, stability data and other data for various products. It’s very easy to go in this system and access key data that is needed for IND or BLA writing. In addition, the system provides quick access to teams for quick decision making and reduces batch failure risks.

The system is available for integration with external systems such as Pl, LIMS, and ELN. The use case for Data Module is consistent across companies of all scales. The system is universal for all companies. The only difference is the degree of integration with external systems such as ELN, Pl, and LIMS systems.